INDUSTRY SOLUTIONS

Power industry

Electric power is the energy driven by electric energy. Discovered in the 1870s, the discovery and application of electricity set off a second upsurge of industrialization. It has become one of the three scientific and technological revolutions in the world since the 18th century in human history. Since then, science and technology has changed people's lives. The large-scale power system emerged in the 20th century is one of the most important achievements in the history of human engineering science. It is a power production and consumption system composed of power generation, transmission, transformation, distribution and consumption. It converts the primary energy of nature into electricity through mechanical energy devices, and then supplies electricity to users through transmission, transformation and distribution.

Solution advantages

The transmission of electrical energy, along with the transformation, distribution, and consumption of electricity, constitutes the overall function of the power system. By transmitting electricity, power plants that are far apart (up to thousands of meters) are connected to load centers, allowing the development and utilization of electricity to exceed regional limitations. Compared with the transmission of other energy sources (such as coal and oil transportation), transmission has the advantages of low loss, high efficiency, flexibility and convenience, easy regulation, and less environmental pollution; Transmission can also connect power plants in different locations and implement peak valley regulation. Transmission is an important manifestation of the superiority of electricity utilization, and in modern society, it is an important energy artery.

Transmission lines can be divided into overhead transmission lines and underground transmission lines according to their structural form. The former consists of line towers, conductors, insulators, etc., and is erected on the ground; The latter mainly uses cables and is laid underground (or underwater). Transmission can be divided into DC transmission and AC transmission based on the nature of the transmitted current. In the 1880s, direct current transmission was first successfully achieved, but was later replaced by alternating current transmission in the late 19th century due to limitations in voltage rise (transmission capacity is roughly proportional to the square of the transmission voltage). The success of AC transmission ushered in the era of electrification in the 20th century. Since the 1960s, due to the development of power electronics technology, there have been new developments in DC transmission, which, in conjunction with AC transmission, have formed a hybrid AC DC power system.

The level of transmission voltage is the main indicator of the development level of transmission technology. By the 1990s, the commonly used transmission voltages in various countries around the world were high voltage transmission of 220 kV and above, ultra-high voltage transmission of 330-765 kV, and ultra-high voltage transmission of 1000 kV and above.

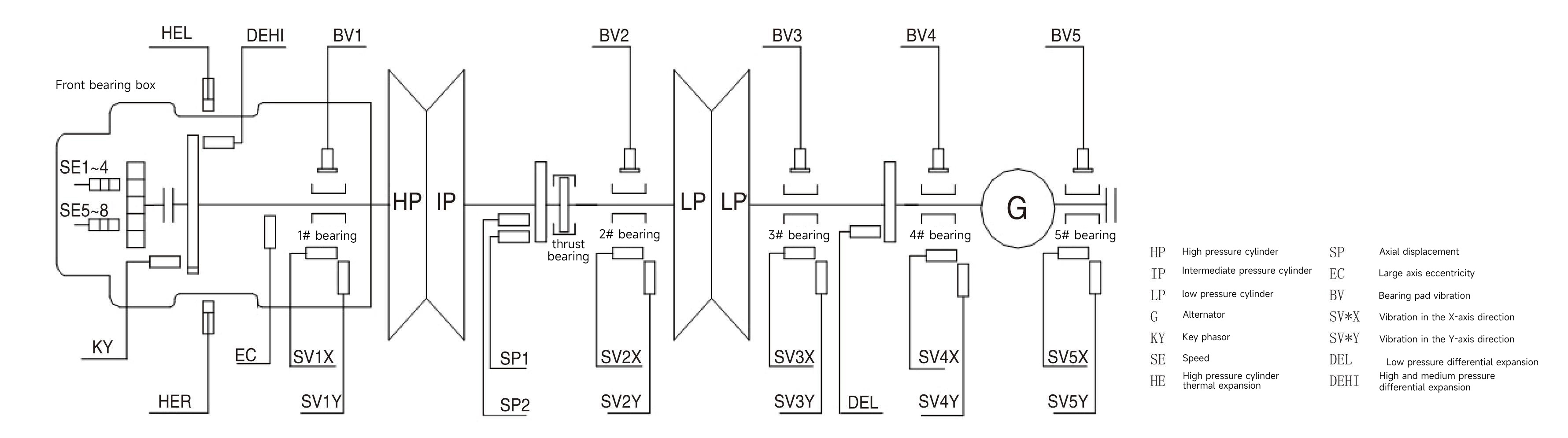

A thermal power plant 135MW unit thermal power generation project in Henan Province

In modern thermal power generation, due to the particularity and complexity of the production process and equipment operation, the equipment components are in overload fatigue operation for a long time, which greatly increases the frequency of equipment maintenance and replacement. In the long run, the safe and efficient production cannot be guaranteed, but the equipment maintenance and operation costs of the enterprise are increased. Therefore, it is of great significance to monitor the operation status of key equipment. Taking the 135MW steam turbine unit as an example, the following figure is the schematic diagram of TSI measuring point configuration and sensor installation position.

Comprehensive product and service series to create plant-wide solutions

Main products of various series applied in the industry

| Serial Number | Product Name | Model | Supporting sensors |

| 1 | chassis | XDG5000/000 | |

| 2 | Power module | XDG5000/001 | |

| 3 | Main control management module | XDG5000/002 | |

| 4 | Two out of three module | XDG5000/161 | |

| 5 | Overspeed module | XDG5000/053 | XDG1300 series magnetoresistive speed sensor |

| 6 | Bearing vibration module | XDG5000/012 | XDG1100 series magnetoelectric speed sensor |

| 7 | Shaft vibration module | XDG5000/022 | XDG1000 series eddy current sensor |

| 8 | Displacement module | XDG5000/032 | XDG1000 series eddy current sensor |

| 9 | Speed/Zero Speed/Impact Submodule | XDG5000/051 | XDG1000 series eddy current sensor |

| 10 | Eccentric module | XDG5000/061 | XDG1000 series eddy current sensor |

| 11 | Journey module | XDG5000/072 | XDG-LVDT series displacement sensor |

| 12 | Keyphasor module | XDG5000/150 | XDG1000 series eddy current sensor |

| 13 | Software |