INDUSTRY SOLUTIONS

Coal Industry

The coal industry chain mainly includes upstream natural resource coal mining, selection, and subdivision of coal varieties. From coal gangue to coal mine to raw coal, it can be divided into brown coal, bituminous coal, and anthracite according to the proportion of volatile matter, and the degree of coal gasification increases in sequence. There are more types of segmented coal varieties, including injection coal, coking coal, and blended coking coal (lean coal, lean coal, fat coal, 1/3 coking coal, etc.), steam coal (sticky coal, non sticky coal, long flame coal, etc.), and brown coal. The midstream is roughly divided into steam coal, coking coal, and anthracite through the processing and transportation of raw coal. These three types of coal have different uses, corresponding to the downstream applications of coal, including real estate, chemical industry, infrastructure, machinery, household appliances, and other application links. The operation and development of the downstream coal chemical industry mainly rely on the material balance and cascade utilization of coal resource input. Through the step-by-step processing and production of various upstream and downstream links, intermediate or final products of coal chemical industry are formed to meet market demand.

Advantages of solution

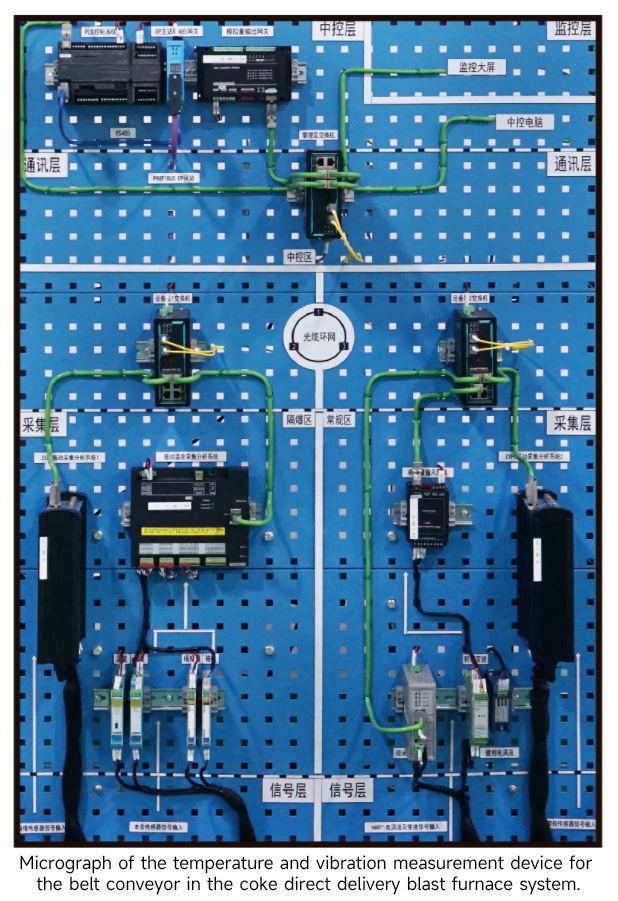

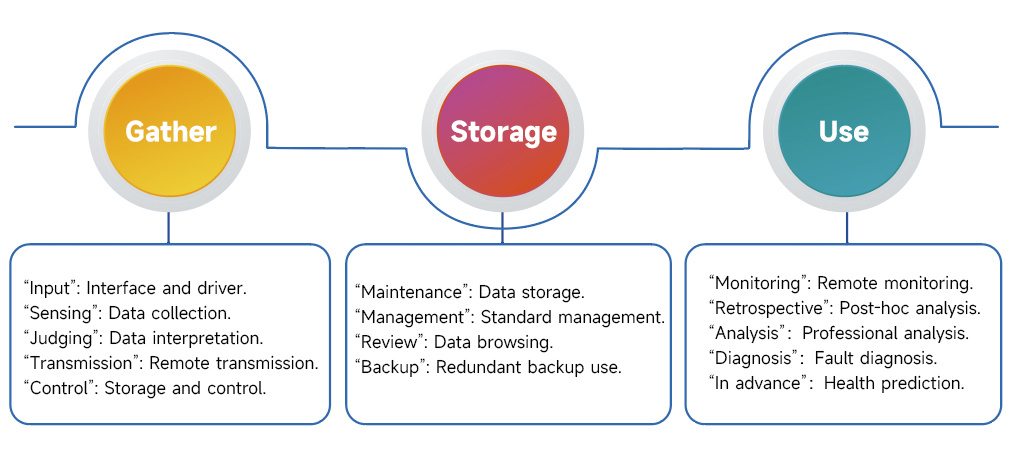

Conduct status monitoring on important operating parts of belt conveyor equipment (motors, reducers, bearings, etc.), continuously measure vibration and temperature data of the tested object, and analyze its health status.

System composition:

The software and database are deployed on the server using a B/S architecture, and the management terminal accesses the server through a browser.

Divide the network according to the area where the belt conveyor belongs, and use fiber optic ring network communication between the ring network and the backend server.

The six major modules of the system include:

Operation monitoring management, fault alarm management, technical data management

Decision support management, collection device management, and system information management.

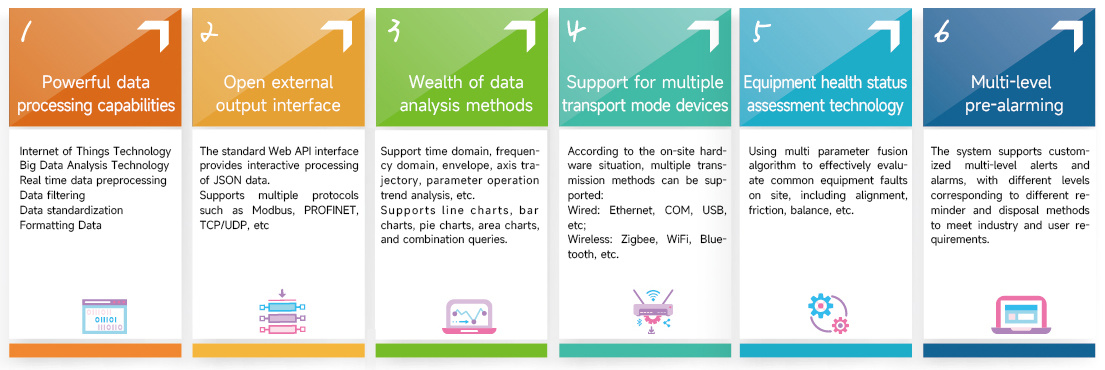

Software features:

Comprehensive product and service series to build plant-wide solutions

Main products of various series applied in the industry

| Serial Number | Product Name | Model | Supporting sensors |

| 1 | sensor | XDG3212Y | XDG1100 series magnetoelectric speed sensor |

| 2 | transmitter | XDG3288G | PT100 temperature sensor, XDG1100 magnetoelectric speed sensor |

| 3 | Wireless intelligent vibration transmitter | XDG2901/XDG2905 | |

| 4 | Vibration data collector | ZXP6A |